GD-searje diafragmakompressor parametertabel

Xuzhou Huayan Gasapparatuer Co., Ltd.is in foaroansteande wrâldwide leveransier fan gaskompresje-oplossingen. Mei opboude ekspertize yn ûntwerp en produksje oer tsientallen jierren, hat ús bedriuw wiidweidige produksjemooglikheden dy't profesjoneel smeden, jitten, waarmtebehanneling, lassen, presyzjebewerking, gearstallingstests en kwaliteitsverifikaasjeprosessen omfetsje. Stipe troch in tawijd technysk team fan 120 professionals en in útwreide produksjefoarsjenning fan 90.000 m², ûnderhâlde wy avansearre technyske testapparatuer en strange kwaliteitskontrôlemetoaden om superieure produktprestaasjes te garandearjen.

Wy binne by steat om apparatuer op maat te ûntwerpen, te produsearjen en te ynstallearjen neffens spesifike klantparameters, en berikke op it stuit in jierlikse produksjekapasiteit fan 500 gaskompressor-ienheden. Us technyske treflikens makket de ûntwikkeling mooglik fan kompressors mei ûntladingsdrukken oant 100 MPa, dy't foldogge oan de meast easken yndustriële easken.

Mei in wrâldwide oanwêzigens dy't him útwreidet nei mear as 50 lannen oer fiif kontininten, ynklusyf wichtige merken lykas Yndoneezje, Egypte, Fietnam, Súd-Korea, Tailân, Finlân, Austraalje, Tsjechje, Oekraïne en Ruslân, leverje wy folsleine turnkey-oplossingen foar kliïnten wrâldwiid. Us ynset foar operasjonele treflikens soarget derfoar dat elke klant apparatuer mei hege prestaasjes krijt, kombinearre mei profesjonele technyske stipe en responsive tsjinst.

Fjouwerkante meter

TECHNYSK TEAM

PRODUKSJE-ERVARING

Eksportearjende lannen

A diafragmakompressoris in spesjalisearre positive ferpleatsingskompressor dy't bekend stiet om syn fermogen om gassen te behanneljen mei útsûnderlike suverens, gefoelichheid of gefaar sûnder fersmoarging of lekkage. Oars as tradisjonele pistonkompressors brûkt it in fleksibel, hydraulysk oandreaun diafragma om it komprimearre gas te isolearjen fan it smeerde krukas en de piston.

Wichtige funksjes:

1.Hermetyske ôfslutingIt metalen of elastomeerdiafragma makket in folsleine, lekfrije barriêre tusken it gas en de hydraulyske floeistof/smeermiddels. Dit is syn definiearjende skaaimerk.

2.Nul fersmoargingGarandearret dat it komprimearre gas absolút oaljefrij en net fersmoarge bliuwt troch smeermiddels of slijtdeeltjes fan it oandriuwmeganisme. Essensjeel foar tapassingen mei hege suverens.

3.LekprevinsjeEliminearret praktysk flechtige útstjit, wêrtroch it kritysk is foar it omgean mei giftige, brânbere, eksplosive of miljeuskealike gassen.

4.Hege drukkapasiteitYn steat om tige hege ûntladingsdrukken te berikken (faak oant 3000 bar / 43.500 psi en mear), foaral yn konfiguraasjes mei meardere stadia.

5,Alsidige gasbehannelingGeskikt foar it komprimearjen fan in breed skala oan gassen, ynklusyf tige reaktive, korrosive, ultra-suvere, djoere of gefaarlike typen dy't beskeadigje of fersmoarge wurde soene troch oare kompressorûntwerpen.

6,Matige streamratenTypysk ûntworpen foar lege oant middelgrutte streamingsnelheden yn ferliking mei grutte suverjende of sintrifugale kompressors.

Geskikte gassen

Geskikte gassen

1.Petrochemyske en gemyske ferwurkingKompresje fan tige korrosive tuskenprodukten, giftige reaktanten (bygelyks yn PVC-produksje mei Cl₂), katalysatorregeneraasjegassen, wetterstofkompresje foar hydrokrakers/hydrotreaters wêr't suverens kritysk is.

2.Oalje en gasUnderseeske gaskompresje, gasynjeksje (ferbettere oaljewinning), wetterstofkompresje foar raffinaderijen.

3.HealgeleiderproduksjeEssensjeel foar it leverjen fan ultra-hege suverens (UHP) en gefaarlike spesjaliteitsgassen (lykas AsH₃, PH₃, SiH₄) oan fabrikaazjeark sûnder fersmoarging.

4.Analytysk & LaboratoariumLeverjen fan suvere, fersmoargingsfrije dragergassen, kalibraasjegassen en monstergassen foar ynstruminten lykas GC-MS.

5,Loftfeart en testenHegedrukgasfoarsjenning (He, N₂) foar it testen fan raketkomponinten, druksystemen, wyntunnels.

6,Medysk en farmaseutyskeProduksje en botteljen fan medyske gassen mei hege suverens (O₂, N₂O), sterile loft foar prosessen.

7,Nukleêre yndustry: Omgean mei heliumkoelmiddels of dekgassen.

8,Enerzjy en wetterstofWetterstofkompresje foar brânstofsellen, wetterstoftankstasjons (HRS), en ûndersyk nei wetterstofproduksje/opslach.

9.MiljeutechnologyKomprimearjen fan fongen CO₂ foar opslach of gebrûk (CCUS).

| Model | Koelwetter (L/oere) | Trochstreaming (Nm³/oere) | Ynlaatdruk (MPa) | Útlaatdruk (MPa) | Ofmjittings L×B×H (mm) | Gewicht (kg) | Motorfermogen (kW) | |

| 1 | GD-120/4-80 | 3000 | 120 | 0.4 | 8.0 | 3000 × 1600 × 1400 | 4000 | 30 |

| 2 | GD-130/0.98-11 | 3000 | 130 | 0.098 | 1.1 | 3000 × 1800 × 1600 | 4000 | 30 |

| 3 | GD-150/2-20 | 3000 | 150 | 0.2 | 2.0 | 3000 × 1800 × 1600 | 4000 | 37 |

| 4 | GD-100/0.1-5 | 4000 | 100 | 0.01 | 0.5 | 2800 × 1500 × 1500 | 3000 | 18.5 |

| 5 | GD-100/5.5-200 | 5000 | 100 | 0.55 | 20 | 3200×2000×1600 | 4500 | 45 |

| 6 | GD-80/0.12-4 | 5000 | 80 | 0.012 | 0.4 | 2800 × 1600 × 1500 | 3800 | 15 |

| 7 | GD-60/0.3-6 | 4000 | 60 | 0.03 | 0.6 | 2800 × 1600 × 1500 | 4000 | 15 |

| 8 | GD-70/0.1-8 | ,3800 | 70 | 0.01 | 0.8 | 3000 × 1600 × 1250 | 5000 | 18.5 |

| 9 | GD-40/0.02-160 | 5000 | 40 | 0.02 | 16 | 2800 × 1460 × 1530 | 3000 | 22 |

| 10 | GD-100/0.5-6 | 2000 | 100 | 0.05 | 0.6 | 3000×2000×1560 | 6000 | 18.5 |

| 11 | GD-36/1-150 | 4000 | 36 | 0.1 | 15 | 3000×1500×1500 | 4000 | 45 |

| 12 | GD-35/0.7-300 | 4000 | 35 | 0.07 | 30 | 3000 × 1600 × 1500 | 4000 | 22 |

Wy hawwe ynternasjonaal erkende sertifikaten, ynklusyfCEenISOnoarmen (akkreditearre trochIAF), lykasECMerkenning fan neilibjen fan regels. Dizze sertifikaasjes demonstrearje ús ûnwrikbere ynset foar kwaliteit, feiligens en miljeuferantwurdlikens:

- CE-markeringsoarget foar neilibjen fan EU-feiligens-, sûnens- en miljeuregeljouwing, wêrtroch frije merktagong yn hiel Europa garandearre wurdt.

- ISO-sertifikaasje(stipe troch IAF-akkreditaasje) validearret ús neilibjen fan wrâldwiid benchmarkearre kwaliteitsbehearsystemen, wêrtroch't de operasjonele konsistinsje en it fertrouwen fan klanten ferbettere wurde.

- ECM-erkenningûnderstreket ús ôfstimming mei yndustryspesifike technyske en prestaasjenormen.

As jo merk of projekt ekstra sertifikaasjes fereasket (bygelyks,API,ASME, of regiospesifike goedkarringen), sil ús erfarne technyske en neilibingsteam mei jo gearwurkje om effisjint de nedige sertifikaasjes te krijen. Wy passe ús prosessen oan om te foldwaan oan jo regeljouwingseasken, wêrtroch't naadleaze merkyngong foar ús apparatuer garandearre wurdt.Foar sertifikaasjestipe of ferdúdliking, nim dan kontakt mei ús op om oanpaste oplossingen te besprekken.

Ús90.000+ fjouwerkante metermoderne produksjefasiliteit, bemanne troch120+professionals, leveret oanpaste yngenieursoplossingen mei presyzjeproduksjemooglikheden. Útrist mei 20 avansearre CNC-ferwurkingssintra, behannelje wy wurkstikken oant1200mmyn diameter mei krektens op mikronnivo (0,01 mmStrang kwaliteitskontrôleprotokollen omfetsje folsleine ynspeksjes fan krityske komponinten mei CMM (koördinaatmjitmasines) en mearfaze ladingstests troch sertifisearre yngenieurs nei de gearstalling. Elke ienheid ûndergiet prestaasjevalidaasje om te foldwaan oan ASME/API-noarmen en klantspesifikaasjes, stipe trochISO 9001-sertifisearrekwaliteitsbehear foar traceerbere, betroubere levering.

Wy brûkefumigaasjefrijmassief houten ramtwurkensertifisearre troch ISO ynternasjonale eksportkarantêne-noarmen. Yntern fersterke mei kanaalstiel foar trijediminsjonale stipe, de bûtenkant is omwikkele mei 0,8 mm ferdikke metalen hoekebeskermers en befeilige by de gewrichten meiwetterdichte galvanisearre stielen riemenDit ûntwerp soarget foar ympaktbestindigens, kompresjebestindige duorsumens, fochtbeskerming en roestprevinsje tidens it ferfier, wêrtroch't jo guod feilich oankomme.

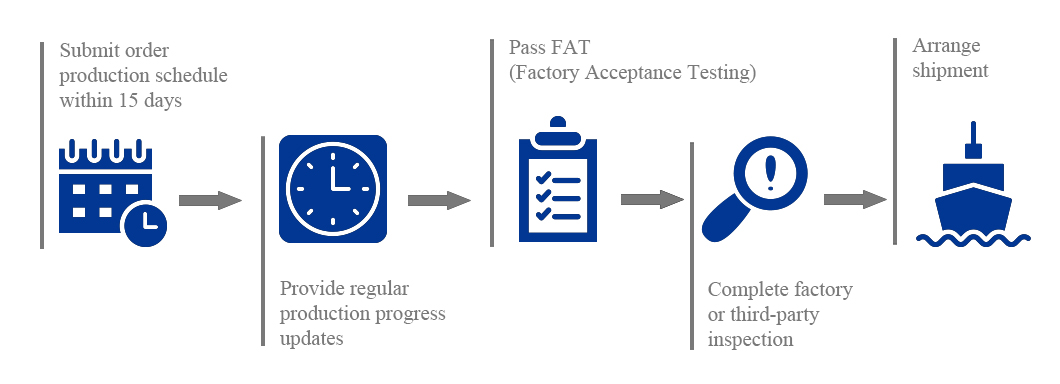

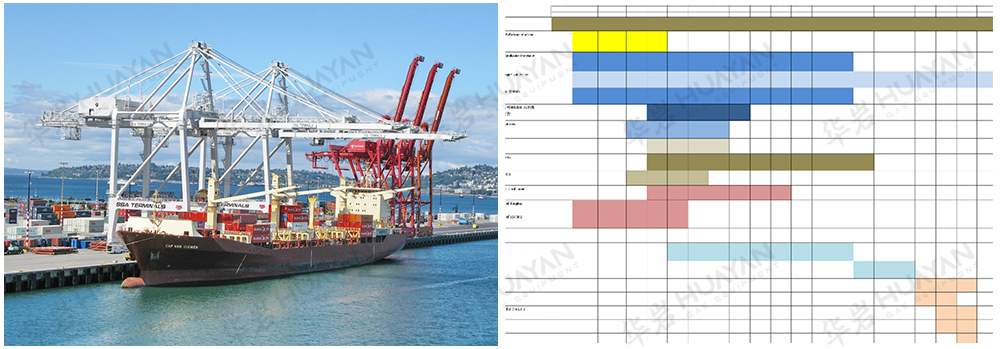

Us bedriuw sil oanpaste leveringsskema's ûntwikkelje foar jo projekt, stipe troch yntegreare logistike oplossingen dy't dekking biede.loft-, see- en lânferfier.

Troch gebrûk te meitsjen fan it nasjonale netwurk fan Sina en wrâldwide gearwurkingsferbannen, soargje wy foar effisjinte grinsoverschrijdende operaasjes mei real-time tracking, stipe foar dûaneôfhanneling en bonded warehousing-mooglikheden. Multimodale fleksibiliteit garandearret kosten-effektive en tydlike levering foar alle soarten fracht.

1. Hoe kinne jo in rappe offerte krije foar in gaskompressor?

1) Trochstreamingssnelheid/kapasiteit: ___ Nm3/oere

2) Sûch-/ynlaatdruk: ____ Bar

3) Untladings-/útlaatdruk: ____ Bar

4) Gasmedium: _____

5) Spanning en frekwinsje: ____ V/PH/HZ

2. Hoe lang is de levertiid?

De levertiid is sawat 30-90 dagen.

3. Hoe sit it mei de spanning fan produkten? Kinne se oanpast wurde?

Ja, de spanning kin oanpast wurde neffens jo fraach.

4. Kinne jo OEM-oarders akseptearje?

Ja, OEM-oarders binne tige wolkom.

5. Sille jo wat reserveûnderdielen fan 'e masines leverje?

Ja